ABLE Reducer Model

ABLE Reducer Model

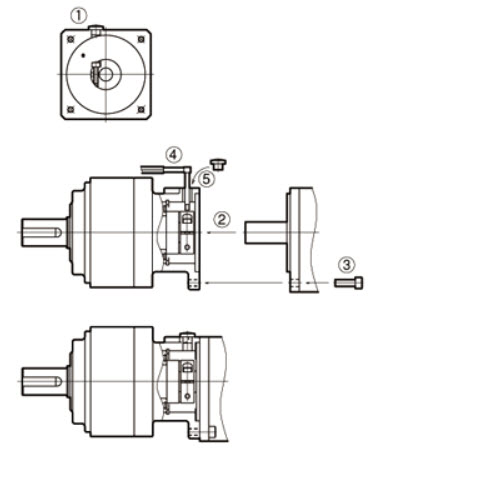

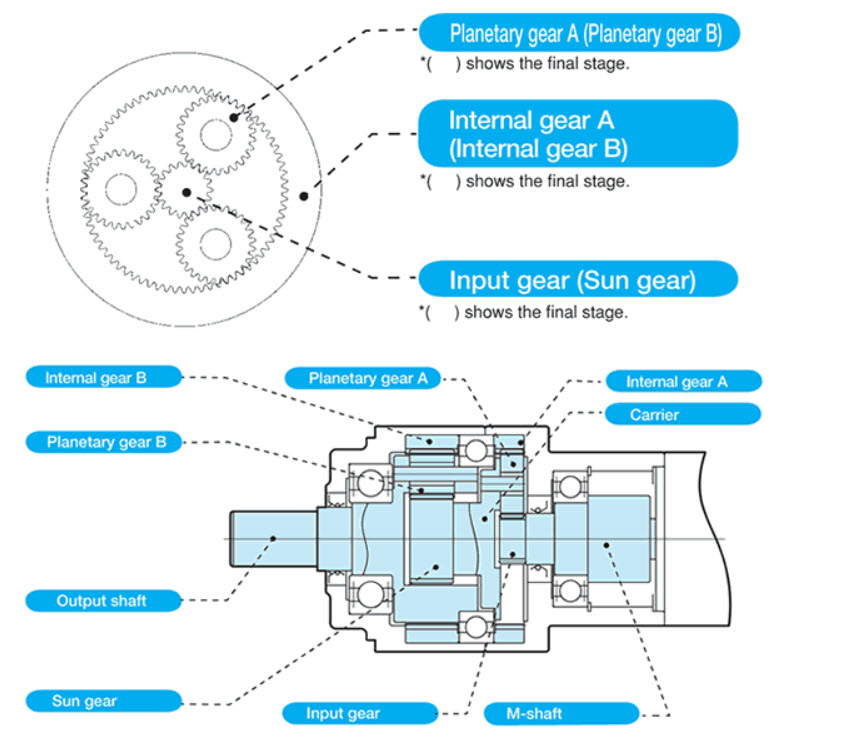

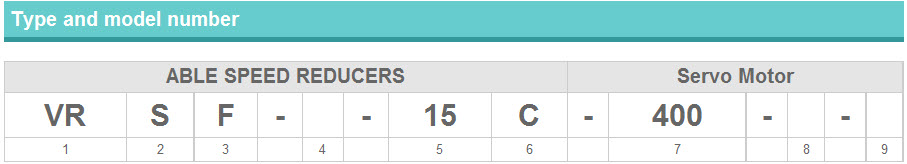

S:Input part

K:Coupling (Straight shaft, with keyway) D-cut is available only for K type.

A:Adapter type (Please contact us for the details.)

Installation and output shaft direction

F: Flange type, Mounting free

D: With D-fl ange type, Mounting free

Reducer specifi cations

Blank: Standard backlash

LB : Low backlash

PB : Precision backlash

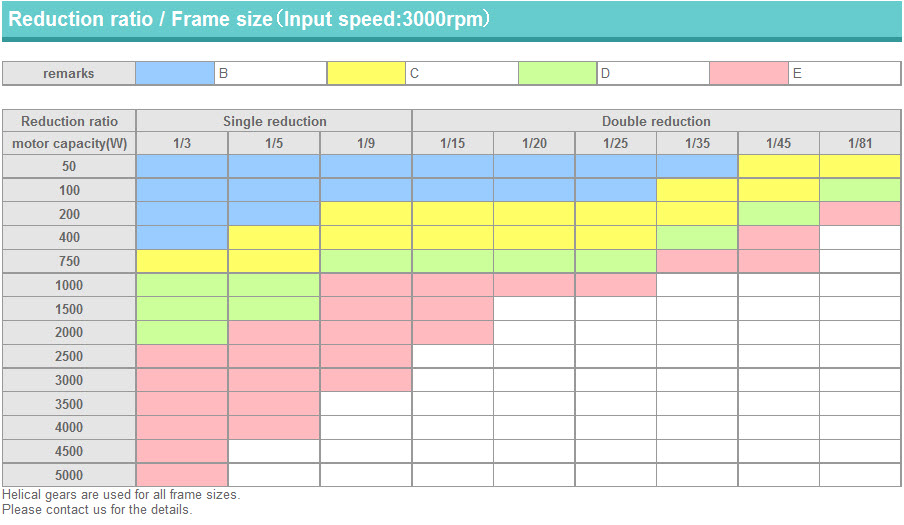

Reduction ratio

Single reduction 3, 5, S9

Double reduction 15, 20, 25, 35, 45, 81

Frame size B,C,D,E

Applicable servo motor capacity (W)

Servo motor manufacturer

Model number of servo motor

*Please specify the servo motor's model number.