Products

ServoTube Linear Actuators

ServoTube linear incorporate a long-life lubrication-free bearing. Built-in position feedback delivers up to 12 micron repeatability. Indusry standard mounting simplifies installation. Actuators are IP67 rated and deliver continuous force from 7-276 N.

ServoTube Linear Motor Components

ServoTube linear motor components are designed to integrate into OEM machinery and require an external bearing. Loads can be mounted directly to the rugged forcer. Built-in position feedback with up to 12 micron repeatability simplifies installation. Motor components are IP67 rated and deliver continuous force from 7-276 N.

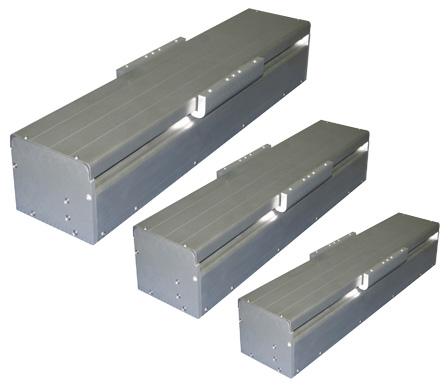

Linear Motor Modules

Linear motor modules are ready-to-use and equipped with bearing rail, limit switches and drag-chain. A linear encoder option is available for high precision applications. Consult Copley sales representative to specify a module for your application.

Linear motor (Module,Planar)

|

LMML010 |

|

LMML020 |

|

LMML030 |

|

LMML040 |

|

How to configure the Module Linear Motor & Specialities of Multi-module Linear Motor with High Performance! Force Reference Chart |

• iron core, direct drive brushless linear motors

• low cogging design

• compact form factor (coil length 96 mm; overall height 34 mm)

• maximum peak force 794 N, maximum continuous force 174 N

• iron core, direct drive brushless linear motors

• low cogging design

• 4 models (ACM2, 3, 4, 5) with coil lengths from 200 mm to 704 mm

• maximum peak force of 10,500 N, maximum continuous force 7379 n

• zero cogging

• low moving mass and high force to mass ratio

• 4 models (AUM2, 3, 4, 5)

• suitable for high accelerations (10G or more) and high speed

• also suitable for high precision applications with air bearings

• zero cogging

• compact size with high force to mass ratio

• suitable for short stroke and high acceleration applications

• Effective stroke from 200 mm to 2500 mm

• Offers high speed, high acceleration and high precision

• Constructed with dual precision Rexroth linear guides with 4 Rexroth ball chain runner blocks

• Optional conventional cover, standard cover, clean room shielded cover or bellow cover

• Integrated with linear encoder, limit sensor and reference mark for homing

• Suitable for carrying high non-cantilever load or moderate cantilever load

• Effective stroke from 200 mm to 2500 mm

• Offers high speed, high acceleration and high precision

• Constructed with a single precision Rexroth linear guide with 2 Rexroth ball chain runner blocks

• Optional bellow cover for SGL78, standard cover or clean room shielded cover for SGL80/100/120

• Integrated with linear encoder, limit sensor and reference mark for homing

• Suitable for carrying light load but strictly not for cantilever load

• Effective stroke from 200 mm to 1600 mm

• Offers high speed, high acceleration and high precision

• Constructed with a single corrosion resistant, wide precision Rexroth linear guide with 2 Rexroth ball chain runner blocks

• Integrated with linear encoder, limit sensor and reference mark for homing

• Designed for high speed pick and place applications

• Suitable for short stroke applications (50 mm)

• Offers high acceleration and high precision

• Constructed with a single corrosion resistant precision Rexroth linear guide with 2 Rexroth ball chain runner blocks

• Integrated with linear encoder, limit sensor and reference mark for homing

• Suitable for high speed vertical pick and place applications

• Compact size allows multiple modules to be placed side by side on a single carriage